LAC VIROT PROJECT

LOCATION: NEWFOUNDLAND AND LABRADOR, CANADA

Project Overview:

NI43_101_for the LacVirot Project_FINAL_FEB 19- 2025

Lac Virot is an iron-ore deposit located in southwestern Labrador, near the border of Québec and Labrador, and just 12 km away from Labrador City. This deposit boasts an identified exploration target of 500-700 Mt iron mineralized formation with open boundaries and an average of 28%-32% total Fe in three out of eight identified targets. The area is part of the Labrador Trough geological belt, known for its abundant iron-ore reserves and well-developed infrastructure, amenities, and low-cost zero-emission hydropower.

The Project is an ESG-compliant mining development and an industrial project that prioritizes zero-carbon emission goals in all aspects of iron ore mining and processing, with a focus on producing zero-emission green steel. Red Paramount aims to design and construct a fully sustainable facility fueled by renewable energy for the Lac Virot project in alignment with global energy and climate objectives.

Project History

Newfoundland and Labrador’s rich mineral potential has been known since the early 19th century, and the province has been the leading iron ore producer in Canada for the past five decades. The Lac Virot area drew the attention of the Iron Ore Company of Canada, which conducted the initial exploration, spurring growing interest in iron ore mining in the region.

The most extensive exploration campaign in the Lac Virot property to date was undertaken by Ridgemont Iron Ore Corporation in 2011. Through successful rounds of geological mapping, airborne geophysical work, and 12,000 meters of drilling between 2011 and 2013, Ridgemont generated promising exploration results. However, the project was put on hold and later sold due to the prolonged downturn in the iron ore market.

Red Paramount has acquired 100% ownership of the Lac Virot project based on improved market fundamentals and intends to build on the positive historical exploration results. The company is committed to advancing the project through the mine development life cycle and ultimately producing zero-emission green steel using sustainable and innovative practices.

Geophysics:

The combined results of the geological investigations and airborne geophysical survey indicate:

- The Sokoman Iron Formation units—similar to those encountered in nearby mines and advanced exploration projects—are on the Lac Virot property.

- The delimiting of the faulted D1 folds and the late northwest-trending fault offsets.

Several geological investigations were conducted in the western Labrador area after the 1950s for nearby mines, and some results can be used for the project, considering their proximity. Airborne magnetic surveys revealed iron-ore mineralization of substantial thickness at or close to the surface. Based on airborne geophysics and surface mapping, a rough estimate of the property’s potential cumulative strike length of iron formation is more than 20 km.

Drilling:

Additional geophysics work was conducted in 2012 on the 12,000 m exploratory drilling program focused on targets in the eastern and southern areas of the project. The exploration identified:

- 16 km of high-magnetic strike iron formation containing iron between 15% and 42%

- The Sokoman Iron Formation maintains the typical 100–140 m actual thickness throughout the district

- The accuracy of the airborne geophysical works in three drilled areas and the other five identified targets, including three high-potential hematite DSO zones (60.50% total Fe), remain to be explored.

- Substantial ore bodies are close enough to the surface to potentially be mined from the surface via a series of open pits. Other, deeper ore bodies, probably related to the ones closer to the surface, have also been encountered during drilling.

Further drone-driven airborne geophysical work and a round of exploratory drilling are planned for a 2022 program. Further planned engineering works should allow the preparation of more detailed mine planning, applying economic parameters and definition of a NI 43-101- and JORC-compliant resource. Between 2022 and 2023, the five previously unexplored drilling targets will be investigated, followed by infill drilling the year after.

Mineral Resource Estimates

The mineral resource estimate is based on results from 43 diamond drill holes totalling 11,713 meters drilled in 2012. To model the geological and mineral resources, wireframes were created from drill hole information, and grades were interpolated using an Inverse Distance estimation technique. Block models (25m x 25m x 10m) were used, and grades for Total Iron (TFe%), Iron Oxide, Manganese Oxide, Silicon dioxide, and Phosphorus pentoxide were modelled.

The samples were analyzed for Total Iron using X-ray fluorescence, and the magnetic component was determined by Satmagan magnetic analysis. Furthermore, the data used for the mineral resource estimate is supported by industry-standard Quality Assurance and Quality Control procedures that were carried out by certified independent analytical laboratories.

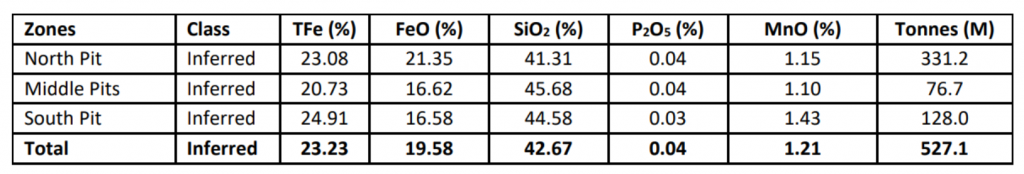

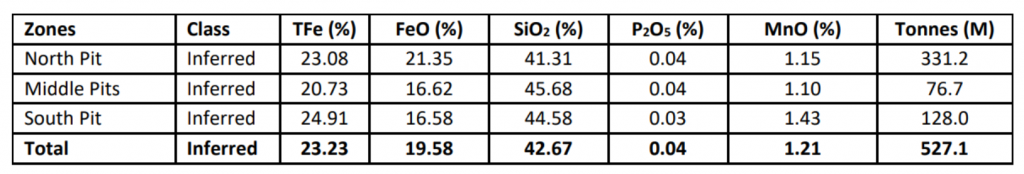

The following table sets out the particulars of the mineral resource estimate at 15% cut-off grades for the pit-constrained scenario:

2025 Preliminary Economic Assessment (PEA)

PEA highlights a world-class iron ore project with substantial resources, low estimated production costs, and strategic access to infrastructure. The Project is positioned to supply high-quality DR-grade iron concentrate to the growing low-carbon steel industry.

• Key PEA Highlights:

- Mineral Resource Estimate: 495.2 million tonnes of inferred resources at 23.33% Fe, with potential for future resource expansion

- Strategic Minerals: high-purity iron ore is positioned to play a critical role as a new strategic mineral for green steel manufacturing to support global demand for decarbonized steel and Newfoundland and Labrador is well-positioned to maximize this opportunity to secure economic and social benefits for the province

- Projected Annual Production: Over 2.5 million tonnes per year of DR-grade iron concentrate

- High-Quality Product: Expected concentrate grade of 67.5% Fe with low impurities, making it an ideal feedstock for DR steelmaking

- Strategic Location: Proximity to the Quebec North Shore & Labrador Railway and the deepwater port at Sept-Îles, enabling efficient global export

- Low Operating Costs: Competitive cost structure leveraging existing infrastructure and hydroelectric power

- Sustainable Mining Approach: Designed to minimize environmental impact, with filtered tailings and water conservation measures integrated into the plan

- Attractive Economics: Strong internal rate of return (IRR) and net present value (NPV), reinforcing economic viability.

“The completion of this PEA is an important step forward for Red Paramount and the Lac Virot Project, we are committed to developing this project not only to support transition of steel industry to low carbon production but also in a way that benefits all stakeholders, especially local communities and First Nations.” said Farzad Nader, Chief Operating Officer of Red Paramount Iron Ltd.”

“Lac Virot is ideally located in one of the world’s most prolific iron ore regions, just 8 km from Labrador City and right next to the Iron Ore Company of Canada mine. This prime location gives us a unique advantage, allowing us to use existing infrastructure, keep costs down, and accelerate development process. With this strategic advantage, Lac Virot will play a role in supplying material for the steel industry’s transition to low-carbon production.

The demand for high-quality, low-impurity iron ore continues to grow, and this PEA highlights the project’s strong economic fundamentals, setting the stage for fast-track development. Looking ahead, we see significant potential with five additional exploration targets and opportunities for process efficiencies as we move toward a feasibility study. Continued drilling and optimization will be key to fully unlocking the value of this asset.”

| PEA Highlights | ||

| Mining | ||

| Strip Ratio (waste:ore) | 1.4 | |

| Total Estimated Mineable Material (Mt) | 545.6 | |

| Mineable Material (Mt) | 227.3 | |

| Processing | ||

| Processing Life (Years) | 27 | |

| Processing Throughput (Mt/a) | 8.4 | |

| Average Fe Grade (%) | 24.3 | |

| Economic Assumptions | ||

| Exchange Rate (US$:C$) | 0.6953 | |

| Discount Rate (%) | 8 | |

| Fe Recovery (% to Concentrate) | 79.1 | |

| Life-of-Mine Fe Production (Mt) | 43.8 | |

| Life-of-Mine Fe 76.5% Production (Mt) | 64.8 | |

| Life-of-Mine Average Annual Fe Production (Mt) | 1.6 | |

| Life-of-Mine Average Fe 76.5% (Mt) | 2.5 | |

| Operating Cost (US$/dmt Concentrate) | 61.89 | |

| Royalty (NSR) (%) | 1 | |

| Capital Expenditure | ||

| Pre-Production Capital (US$ Millions) | 648 | |

| Sustaining Capital (US$ Millions) | 250 | |

| Closure Capital (US$ Millions) | 120 | |

| Project Pre-Tax Economic Results | ||

| Economics | Concentrate Price (US$120/dmt) |

Concentrate Price Plus DR Premium (US$152.2/dmt) |

| Pre-Tax IRR (%) | 17.1 | 27 |

| Pre-Tax NPV (8%) (US$ Millions) | 560.2 | 1,283.1 |

| Pre-Tax NPV (10%) US$ Millions) | 363.8 | 952.5 |

| Pre-Tax NPV (15%) US$ Millions) | 62.3 | 392.1 |

| Life-of-Mine Pre-Tax Cash Flow US$ Millions) | 2674 | 4,74.6 |

The PEA is preliminary in nature and is based, in part, on Inferred Mineral Resources. Mineral Resources are considered too geologically speculative to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves. The project economic analysis was carried out using a discounted cash flow approach on a pre-tax and after-tax basis. The IRR on total investment that is presented in the economic analysis was calculated assuming 100% equity financing.

• Mineral Resource Estimate

The Mineral Resource is reported as Inferred in the table below. The Mineral Resource was estimated using The Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Estimation of Mineral Resources & Mineral Reserves Best Practice Guidelines (2019) and is reported in accordance with the 2014 CIM Definition Standards for Mineral Resources & Mineral Reserves, which have been incorporated by reference in National Instrument 43-101-Standards of Disclosure for Mineral Projects.

Lac Virot Inferred Mineral Resource Estimates above 15% Fe Cut-Off Grade-February 7, 2025

| Name | Classification | Fe (%) |

FeO (%) |

SiO2 (%) |

P2O5 (%) |

MnO (%) |

MagFeSat (%) |

Volume (Mm3) |

Tonnes (M) |

| All Pits | Inferred | 23.33 | 19.61 | 42.40 | 0.04 | 1.22 | 10.85 | 141.5 | 495.2 |

| North Pit | 23.016 | 21.34 | 41.26 | 0.04 | 1.16 | 9.61 | 90.9 | 318.0 | |

| Middle Pit | 20.88 | 16.90 | 45.33 | 0.04 | 1.10 | 10.05 | 17.5 | 61.1 | |

| South Pit | 25.10 | 16.30 | 44.36 | 0.03 | 1.46 | 14.69 | 33.0 | 115.4 |

Notes:

- A fixed density of 3.5 t/m3 was used to estimate the tonnage from block model volumes.

- Mineral Resources are constrained by the pit shell and the topography of the overburden layer.

- The results from the pit optimization are used solely for testing the “reasonable prospects for economic extraction” by an open pit and do not represent an attempt to estimate Mineral Reserves. There are no Mineral Reserves on the Property. The results are used as a guide to assist in the preparation of a Mineral Resource statement and to select an appropriate resource-reporting cut-off grade.

- Mineral Resources, which are not Mineral Reserves, do not have demonstrated economic viability. An Inferred Mineral Resource has a lower level of confidence than that applying to Measured and Indicated Resources and must not be converted to a Mineral Reserve. It is reasonably expected that most of the Inferred Mineral Resources could be upgraded to Indicated Mineral Resources with continued exploration.

- All figures are rounded to reflect the relative accuracy of the estimate, and numbers may not add due to rounding.

- Effective date February 16, 2025.

- The Mineral Resource estimates may be materially affected by environmental, permitting, legal, title, taxation, socio-political, marketing, or other relevant issues.

- Based on a cut-off grade of Fe of 15%.

- Mineral Resources are constrained within Red Paramount mineral rights.

- The pit optimization and base-case cut-off grade of 15% Fe considers a pricing of US$120/t of concentrate at 67.5% Fe (US$160.80/t of concentrate at 67.5%); combined rock processing (US$5.21/t concentrate corresponding to US$1.61/t milled), transportation (US$23.75/t concentrate corresponding to US$7.35/t milled), and general & administrative cost (US$3.75/t concentrate corresponding to US$1.16/t milled) totaling US$13.13/t milled of mineralized material; open pit mining cost of US$3.00/t mined of mineralized material; an average pit slope of 45° for fresh rock; an average pit slope of 20° for overburden; and an average mining recovery of 95%, processing recovery of 80%, and dilution of 5%; and a waste density of 2.9.

• Mine Plan

The PEA outlines a 27-year mine life, leveraging a phased development strategy designed for low initial capital investment with the flexibility to scale-up production based on market demand. The mine plan features four distinct open pits, each mined as a single phase, with extracted material hauled to a centrally located crusher to optimize logistics and minimize haul distances.

• Mine Production & Expansion Strategy

- Initial production begins at 2.5 Mt/a of dry concentrate, with plans for future expansion as market conditions evolve.

- Mining activities ramp up from 7 Mt/a in Year −1 to 20 Mt/a in Year 1, ensuring a smooth transition to full-scale operations.

- By Year 12, total material movement is expected to reach 30 Mt/a, demonstrating the project’s ability to scale efficiently.

- Strategic placement of waste rock stockpiles helps minimize haul distances and optimize site efficiency.

- The project maintains an average strip ratio of 1.4, balancing waste management with ore recovery.

- The PEA highlights a robust mine plan designed for flexibility and scalability, allowing for future production increases to meet expected growing demand for DR-grade iron ore. With a well-structured development approach, the Lac Virot Project is positioned for long-term operational success and efficient scaling as market conditions evolve.

Lac Virot Pit Summary

| Pit | Mineable Material (kt) |

Fe (%) |

FeO (%) |

P2O5 (%) |

Waste (kt) |

Total (kt) |

Strip Ratio (W:O) |

| 1 (Mid) | 15,223 | 23.59 | 21.16 | 0.02 | 14,757 | 29,980 | 0.97 |

| 2 (North) | 61,627 | 23.29 | 21.13 | 0.03 | 77,216 | 138,843 | 1.25 |

| 3 (South) | 78,454 | 24.92 | 16.07 | 0.03 | 95,645 | 174,099 | 1.22 |

| 4 (North) | 71,980 | 24.78 | 22.18 | 0.05 | 130,697 | 202,677 | 1.82 |

| Total | 227,283 | 24.35 | 19.72 | 0.04 | 318,315 | 545,598 | 1.40 |

The PEA demonstrates an initial life-of-mine of approximately 27 years with total production of approximately 227 Mt. However, this represents a point-in-time estimate of the mine plan and approximately half the current Inferred Mineral Resource. The Lac Virot Project follows a phased development strategy, initially processing 2.5 Mt/a of DR-grade concentrate, with plans for expansion based on market demand.

Mine Plan Production

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/9571/241641_image3.jpg

• Process Recovery

The Lac Virot process plant is designed to process 9 million tonnes per year (Mt/a) of iron ore, producing 2.5 Mt/a of high-grade direct reduction (DR) iron concentrate with an iron content exceeding 67.5% Fe. The facility operates year-round with an overall plant availability of 90.3%, ensuring continuous production. The process begins with primary crushing near the Mid Pit, where run-of-mine (ROM) material is reduced in size and transported via an overland conveyor to the plant. Secondary crushing, followed by high-pressure grinding rolls (HPGR), further reduces the ore, preparing it for downstream processing.

After crushing, the material undergoes multi-stage magnetic separation to upgrade the iron content. Initial separation removes non-magnetic material, increasing the iron grade to approximately 40% Fe. Further grinding and intermediate separation refine the concentrate to 50-60% Fe, followed by ultra-fine grinding in a vertical mill for optimal liberation. A final cleaning stage produces a DR grade concentrate, which is thickened and filtered to reduce moisture to below 9%, making it suitable for transport. The plant will employ a dry stack tailings system, minimizing water usage and environmental impact. The majority of the tailings will be stored in exhausted pits, reducing the need for large-scale tailings storage facilities and enhancing site rehabilitation efforts.

• Capital Expenditure

The Lac Virot Project initial capital cost is estimated at US$647.9 million, covering mining, processing, tailings management, and infrastructure development. The estimate, classified as an AACE Class 4 with an accuracy of ±40%, is based on Q1 2025 US$. Key cost components include US$150.6 million for mining, US$207.3 million for the process plant, US$22.5 million for the tailings facility, and US$44.3 million for infrastructure such as access roads, rail transport, and electrical substations.

Sustaining capital over the life of the mine is projected at US$247.5 million, with US$197.1 million allocated to mining fleet maintenance and expansion, with the remainder supporting infrastructure improvements, tailings facility expansions, and environmental management systems. Indirect costs, including Engineering Procurement and Construction Management services and project contingency, amount to US$167.1 million, ensuring smooth execution and risk mitigation.

A structured closure and rehabilitation plan, with a total budget of US$120 million, has been designed to minimize environmental impact and restore the site for potential future land use. Beginning in Year 4, annual allocations of US$5 million will fund progressive rehabilitation efforts, including waste pile stabilization, open pit closure, dismantling of processing facilities, and revegetation of the tailings storage facility. The dry stack tailings facility will undergo final contouring and capping to integrate with the surrounding landscape.

• Estimated Capital and Operating Cost for Lac Virot Project

| Capital Cost Estimate | Operating Cost Estimate | ||||||

| Initial (US$ M) |

Sustaining (US$ M) |

Closure (US$ M) |

Processed (US$/t) |

Concentrate (US$/t) |

|||

| Mining | 150.6 | 197 | – | Mining | 5.01 | 16.03 | |

| Process Plant | 207.3 | 5 | – | Process Plant | 3.93 | 12.93 | |

| Tailings Facility | 22.5 | 25 | 10 | Tailings | 0.68 | 2.23 | |

| Infrastructure | 44.3 | 15 | – | Transportation and Logistics | 5.47 | 18.00 | |

| Subtotal | 424.7 | – | – | Owners Cost | 0.39 | 1.29 | |

| Owners Cost | 51.7 | – | – | Total | 15.48 | 50.48 | |

| Indirect Costs | 115.4 | 5.5 | – | ||||

| Subtotal | 540.0 | – | – | ||||

| Contingency | 107.9 | – | – | ||||

| Closure | – | – | 110 | ||||

| Total | 647.9 | 247.5 | 120 | ||||

• Economic Analysis

The Lac Virot Project economic analysis was conducted using a discounted cash flow model, evaluating both pre-tax and post-tax financial scenarios. Key financial metrics, including NPV and IRR, were calculated on a 100% equity-financed basis, with discount rates ranging from 0% to 12%. The financial model assumes a two-year construction period, followed by a 27-year mine life, with no planned capacity expansion at this stage. Two iron ore pricing scenarios were incorporated: the base case used a Platts TSI IODEX 65% Fe CFR China price of US$120/dmt, while an alternative scenario included a US$32.5/t premium for DR-grade iron concentrate, bringing the total assumed price to US$152.2/t.

Project Pre-Tax Economic Results

| Economics | US$120/dmt | US$152.2/dmt |

| Pre-Tax IRR | 17.1% | 27% |

| Pre-Tax NPV (8%) (US$ M) | 560.2 | 1,283.1 |

| Pre-Tax NPV (10%) US$ M) | 363.8 | 952.5 |

| Pre-Tax NPV (15%) US$ M) | 62.3 | 392.1 |

| Life-of-Mine Pre-Tax cash flow (US$ M) | 2,674 | 4,74.6 |

• Next Steps and Permitting

With the Lac Virot Project demonstrating strong technical and economical viability as a source of DR-grade iron ore concentrate, the next phase will focus on advancing the project toward commercial production. Key priorities include initiating a pre-feasibility study (PFS), exploring other targets, refining metallurgical processes, securing logistics and infrastructure, implementing sustainable tailings management, initiating permitting, and forming strategic partnerships.

The PFS will involve further drilling and resource classification, pit optimization, detailed mine scheduling, geotechnical and hydrological studies, and environmental and social impact assessments. Simultaneously, the permitting process will be initiated to secure necessary approvals, ensuring compliance with environmental regulations and stakeholder requirements. Exploration efforts, including infill and step-out drilling, geophysical surveys, and structural mapping, will further define the deposits. Additional metallurgical testwork will focus on optimizing magnetic separation, flotation conditions, grindability, and comminution, with pilot-scale validation to ensure energy efficiency and cost-effective processing.

A strong commitment to engagement with Indigenous and local communities will be a fundamental part of the project’s development. Initiating discussions and fostering meaningful partnerships with First Nations will be essential to ensuring that Lac Virot is developed in a way that respects Indigenous rights, incorporates traditional knowledge, and maximizes economic and social benefits for local communities. Transparent dialogue and collaboration will be prioritized throughout the permitting and development phases.

Securing logistics and infrastructure remains a key priority for Project execution. This includes advancing agreements for hydroelectric power supply from Nalcor, ensuring a stable and sustainable energy source.

The Churchill Falls transmission line will provide additional energy security, while renewable energy integration will be explored to further reduce emissions. Infrastructure partnerships will be assessed to enhance efficiency and reduce transportation costs, particularly with neighboring mining operations for shared rail and port facilities. Sustainable tailings management will continue to focus on dry stacking and filtered tailings, with further assessment of backfilling exhausted pits to minimize environmental impact and support land rehabilitation.

On behalf of the Board of Red Paramount Iron Ltd.

| Farzad Nader, P.Eng., M.Eng., MBA Chief Operating Officer T 778-837-9165 E farzad.nader@redparamount.ca Red Paramount Iron Ltd. 1188-1095 W Pender Street, Vancouver, BC, V6E 2M6 |

Shervin Teymouri BASc., M.Eng., P.Eng. President & CEO T 604-715-1314 E shervin.teymouri@reparamount.ca Red Paramount Iron Ltd. 1188-1095 W Pender Street, Vancouver, BC, V6E 2M6 |

APPENDIX A

Site Layout

Site Layout

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/9571/241641_430bedaeb4e77a69_002full.jpg

APPENDIX B

Cautionary statement on forward-looking information

This Technical Report contains certain forward-looking information and forward-looking statements within the meaning of applicable securities legislation and may include future-oriented financial information (collectively, forward-looking Information). Forward-looking information in this Technical Report includes, but is not limited to, statements regarding plans and expectations for the “Lac Virot DR Grade Iron Ore Project”, including estimated mine life, mining costs and production rates; estimates of Mineral Resources and the conversation of Mineral Resources to Mineral Reserves; projected metallurgical recoveries; and anticipated environmental liabilities. Forward-looking information can be identified by the use of words such as “will,” “expect,” “achieve,” “product,” “increase,” “plan,” “potential,” “intend,” “anticipate,” “expect,” “estimate,” “target,” “objective” and similar expressions and phrases or statements that certain actions, events or results “may,” “could,” or “should” occur, or the negative connotation of such terms. The material factors or assumptions regarding forward-looking information contained in this Technical Report are discussed in this report, where applicable. Forward-looking information is subject to known and unknown risks, uncertainties and other factors that may cause actual results and developments to differ materially from those expressed or implied by such forward-looking information. Relevant risks and other factors include, without limitation: fluctuations in DR Grade Iron Ore prices; fluctuations in prices for energy inputs, labour, materials, supplies and services; fluctuations in currency markets; operational risks and hazards inherent with the business of mining (including environmental accidents and hazards, industrial accidents, geotechnical incidents, equipment breakdown, unusual or unexpected geological or structural formations, cave-ins, flooding, fire and severe weather); inadequate insurance, or inability to obtain insurance to cover these risks and hazards; employee relations; relationships with, and claims by, local communities and indigenous populations; the ability to maintain existing or obtain all necessary permits, licenses and regulatory approvals in a timely manner or at all; changes in laws, regulations and government practices, including environmental and export and import laws and regulations; legal restrictions relating to mining; and risks relating to expropriation; increased competition in the mining industry. Forward-looking information is designed to help readers understand views as of that time with respect to future events and speaks only as of the date it is made. All the forward-looking information in this Technical Report is qualified by these cautionary statements. Except as required by applicable law, Red Paramount Iron Ltd. and the Qualified Persons who authored this Technical Report assume no obligation to update publicly or otherwise revise any forward-looking information in this Technical Report, whether because of new information or future events or otherwise.

INVEST IN THE BOUNDLESS POTENTIAL OF GREEN MINING

To learn more about Red Paramount Iron and our project, contact us